Digitizing Intrusive Inspections & Port

Operations for Scanport Ltd

Overview

Scanport Ltd, a security technology provider safeguarding critical national infrastructure, sought to modernize the container inspection lifecycle at high-traffic seaports. Their operations relied heavily on manual workflows — particularly for intrusive inspections, bay allocation, driver tracking, and compliance reporting — leading to congestion, inconsistencies, and regulatory risk.

To solve this, we engineered and deployed a comprehensive, scalable ERP system, with a digital-first foundation purpose-built for the unique needs of port security and inspection operations.

The Challenge

Key operational bottlenecks prior to digitization:

Manual Bay Allocation: Agents physically queued at booths to secure bays, creating congestion.

Lack of Real-Time Insight: No unified visibility into queue lengths, inspection progress, or bay availability.

Compliance Gaps: Limited enforcement of check-in, inspection, and release timelines.

Manual Record-Keeping: Incident reports, service visits, and driver enforcement were fragmented across spreadsheets or paper logs.

Disjointed Modules: HR, feedback, and asset data lived in silos — reducing decision-making efficiency.

Objectives

- Digitize and automate intrusive inspection & bay allocation

- Enforce driver limits and inspection timelines

- Provide a real-time dashboard for inspection operations

- Capture incidents, service visits, and feedback electronically

- Centralize HR attendance and asset records

- Improve communication with agents through a WhatsApp chatbot

- Build a scalable, secure infrastructure ready for integration and offline use

Intrusive Inspection & Bay Allocation System (Core)

- Bays are auto-assigned based on container scan verdicts and bay availability

- Agents are assigned dynamically, with time-based auto-unassignment for delays

- Real-time dashboards display inspection status, bay occupancy, and queue lengths

- Overstay logic enforces container movement discipline

Asset Management

& Service Visits

- Tracks scanning equipment and detection units

- Weekly checklist logs and radiation readings recorded digitally

- Service visit reports maintained and linked to each asset

- Preventive maintenance alerts based on usage thresholds

Fault & Incident

Reporting

- Centralized portal for logging operational incidents

- Structured categories and severity tagging

- Escalation flow and status tracking to resolution

Key Modules

Delivered

Driver Count

Enforcement

- Each driver is restricted to 16 inspections per day

- Real-time validation during check-in prevents over-allocation

- Historical records are maintained for compliance audits

Compliance & HSSE

Reporting

- Inspection timestamp enforcement for audit readiness

- Daily, weekly, and monthly compliance reports

- HSSE incident tracking, override logs, and accountability trails

Solution Architecture

Backend API

Django 4.2.6 Django REST Framework

Backend API

Django Channels

Redis

Frontend

Next.js

(PWA-enabled for mobile use)

Backend API

PostgreSQL (Primary)

MS SQL (MPS Sync)

Customer Feedback Portal for Port Agents

Port agents submit structured feedback on key inspection processes, enabling management to track trends and improve operations through a centralized dashboard.

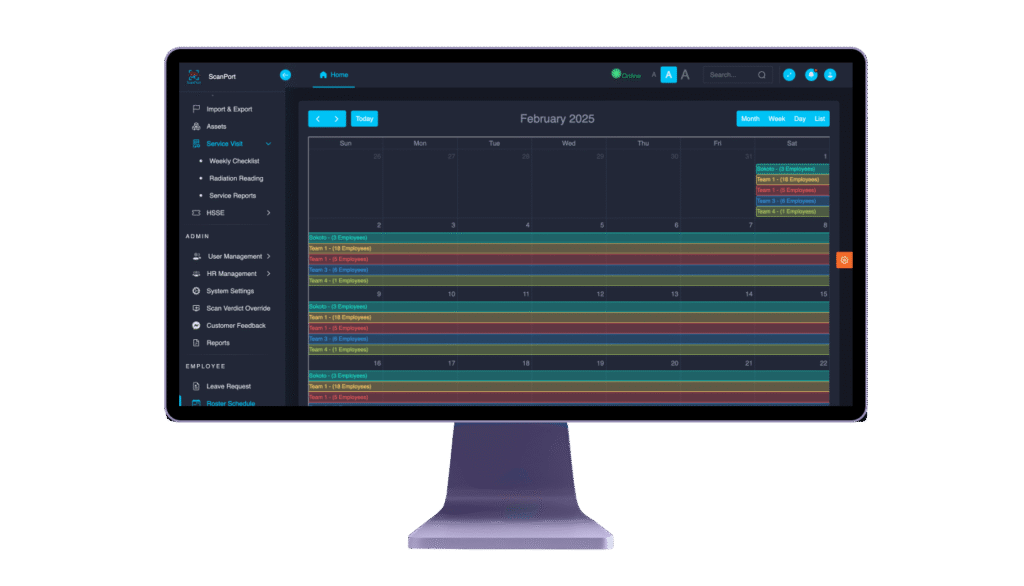

HR Management

- Employee profiles, roles, teams, and rosters

- Attendance logs linked to bay operations and agent activity

- Leave management with approvals and schedule impact insights

- Integrated with intrusive operations to avoid agent conflicts

Real-Time Architecture

Event

Django Signal

Redis Pub/Sub

WebSocket

Client UI

File & Data Processing

EDI & XML Workflow

Security & Compliance

- Role-Based Access Control (RBAC)

- JWT-based API and WebSocket authentication

- End-to-End encryption (in transit and at rest)

- Environment-isolated configuration management

- Audit trails on all critical actions

- Rate limiting and DoS protection per endpoint

Responsive

Design

Fully adaptive layout optimized for all device types and screen sizes

Outcomes &

Impact

Metric

Manual Queueing

Cargo Clearance Time

Inspection Compliance

Operational Visibility

System Uptime

Customer Satisfaction

Metric

Result

Reduced by 90%

Improved by 30%

Enforced via timestamps & rules

100% live dashboard coverage

99.95% (cloud infrastructure)

Improved through chatbot +

feedback

Client

Testimonial

“Before this system, we struggled with manual bottlenecks and compliance tracking. The new ERP has transformed our operations—reducing congestion, improving security, and making bay allocation seamless. It’s been a game-changer for port efficiency.”

George Kwardzi

Deputy Operations Manager

Conclusion

This MPS–Scanport collaboration showcases how high-throughput port operations can be transformed through robust backend engineering, secure data flows, and thoughtful lifecycle tracking. By seamlessly integrating terminal systems with inspection ERP workflows and dashboard analytics, the system now delivers real-time control, regulatory confidence, and operational clarity — container by container.